Survey of Refrigeration Equipment

| Refrigeration equipment can be classified as either self-contained or

remote units. Self-contained equipment houses both the insulated

storage compartments (refrigerated), in which the evaporator is

located, and an uninsulated compartment (nonrefrigerated), in

which the condensing unit is located, in the same cabinet. This

type of equipment can be designed with a hermetically sealed,

semisealed, or an open condensing unit. These units are completely

assembled and charged at the factory and come ready for use with

little or no installation work. Self-contained refrigerating equipment

includes such equipment as domestic refrigerators and freezers,

water coolers, reach-in and walk-in refrigerators, small cold-storage

plants, and ice plants.

Remote refrigerating equipment has the condensing unit installed

in a remote location from the main unit. These types of units

are used where the heat liberated from the condenser cannot

enter the space where the unit is installed or space is limited

for installation. |

Reach-In Refrigerators

Reach-in refrigerators have a storage capacity of 15 cubic feet

or greater. They are mainly used for storing perishable foods,

but they can be found in medical facilities for storing biologicals,

serums, and other medical supplies requiring temperatures between

30°F and 45°F. Standard-size units most frequently used

are those with storage capacities between 15 and 85 cubic feet. Reach-in refrigerators have a storage capacity of 15 cubic feet

or greater. They are mainly used for storing perishable foods,

but they can be found in medical facilities for storing biologicals,

serums, and other medical supplies requiring temperatures between

30°F and 45°F. Standard-size units most frequently used

are those with storage capacities between 15 and 85 cubic feet.

Exterior finishes for reach-in refrigerators are usually of stainless steel,

aluminum, or vinyl, while the interior finishes are usually

metal or plastic, and the refrigerator cabinet is insulated

with board or batten type polystyrene or urethane. Reach-in

refrigerators are normally self-contained, with an air-cooled

condenser, but in larger refrigerators, with remote condensers,

water-cooled condensers are sometimes used. The evaporator is

mounted in the center of the upper portion of the food compartment.

In operation, warm air is drawn by the fan into the upper part

of the unit cooler, where it passes over the evaporator coils,

is cooled, and then is discharged at the bottom of the cooler.

The air then passes up through the interior and around the contents

of the refrigerator. The cycle is completed when the air again

enters the evaporator.

The low-pressure control is set to operate the evaporator on

a self-defrosting cycle, and temperature is thus control led.

Another type of control system uses both temperature and low-pressure

control or defrost on each cycle. The evaporator fan is wired

for continuous operation within the cabinet.

Evaporators in reach-in refrigerators are generally the unit

cooler type with dry coils (Fig. 1). In smaller capacity refrigerators,

ice-making coils, similar to those used in domestic refrigerators,

are often used as well as straight gravity coils. R-12 and R-502

are normally used in these units.

Back to Top |

Walk-In Refrigerators

Walk-in refrigerators are normally larger than reach-in types

and are either built-in or prefabricated sectional walk-in units.

They are made in two types - one for bulk storage of fresh meats,

dairy products, vegetables, and fruits requiring a temperature

from 35°F to 38°F and the other for the storage of frozen

food at temperatures of 10°F or below. The 35°F to 38°F

refrigerators are built and shipped in sections and assembled

at the location they are installed. They can be taken apart, moved,

and reassembled in another area if needed. Standard-size coolers

can be from 24 square feet up to 120 square feet in floor area.

A walk-in refrigerator with reach-in doors is shown in figure

2.

The exterior and interiors of these units are normally galvanized

steel or aluminum. Vinyl, porcelain, and stainless steel are

also used. Most walk-in refrigerators use rigid polyurethane

board, batten, or foamed insulation between the inner and outer

walls. For storage temperatures between 35°F to 40°F,

3 to 4 inches of insulation is generally used. For low-temperature

applications, 5 inches or more of insulation is used. These

refrigerators are equipped with meat racks and hooks to store

meat carcasses.

Walk-in refrigerators also have a lighting system inside the

refrigerator compartment. Most systems have the compressor and

condenser outside the main structure and use either a wall-mounted

forced-air or gravity-type evaporator that is separated from

the main part of the cabinet interior by a vertical baffle.

The operation of the walk-in refrigerator is similar to that

of the reach-in units. The evaporator must have sufficient capacity

(Btu per hour) to handle the heat load from infiltration and

product load.

Back to Top |

Domestic Refrigerators

Most domestic refrigerators are of two types—either a single

door fresh food refrigerator or a two-door refrigerator-freezer

combination, with the freezer compartment on the top portion of

the cabinet, or a vertically split cabinet (side-by-side), with

the freezer compartment on the left side of the cabinet. They

are completely self-contained units and are easy to install. Most

refrigerators use R-22 refrigerant, normally maintaining temperatures

of 0°F in the freezer compartment and about 35°F to 45°F

in the refrigerator compartment. The technician must be able to

perform various duties in the maintenance and repair of domestic

refrigerators, water coolers, and ice machines. This section provides

information to aid you in handling some of the more common types

of troubles. But let us remind you that the information given

here is intended as a general guide and should, therefore, be

used with the manufacturer's detailed instructions.

Single

Door Fresh Food Refrigerator Single

Door Fresh Food Refrigerator

A single door fresh food refrigerator (fig. 3) consists of

an evaporator placed either across the top or in one of the

upper corners of the cabinet. The condenser is on the back of

the cabinet or in the bottom of the cabinet below the hermetic

compressor. During operation, the cold air from the evaporator

flows by natural circulation through the refrigerated space.

The shelves inside the cabinet are constructed so air can circulate

freely past the ends and sides, eliminating the need for a fan.

This refrigerator has a manual defrost, which requires that

the refrigerator be turned off periodically (usually overnight)

to enable the buildup of frost on the evaporator to melt. Both

the outside and inside finish is usually baked-on enamel. Porcelain

enamel is found on steel cabinet liners. The interior of the

unit contains the shelves, lights, thermostats, and temperature

controls.

Two-Door Refrigerator-Freezer Combination

The

two-door refrigerator-freezer combination is the most popular

type of refrigerator. It is similar to the fresh food refrigerators

in construction and the location of components except it sometimes

has an evaporator for both the freezer compartment and the refrigerator

compartment. Also, if it is a frost-free unit, the evaporators

are on the outside of the cabinet. The

two-door refrigerator-freezer combination is the most popular

type of refrigerator. It is similar to the fresh food refrigerators

in construction and the location of components except it sometimes

has an evaporator for both the freezer compartment and the refrigerator

compartment. Also, if it is a frost-free unit, the evaporators

are on the outside of the cabinet.

Because of the two separate compartments (refrigerator-freezer)

and the larger capacity, these types of refrigerators use forced

air (fans) to circulate the air through the inside of both compartments.

The two-door refrigerator also has one of the following three

types of evaporator defrost systems: manual defrost, automatic

defrost, or frost-free.

There are two types of automatic defrosting: the hot gas system

or the electric heater system. The hot gas system, through the

use of solenoid valves, uses the heat in the vapor from the

compressor discharge line and the condenser to defrost the evaporator.

The other system uses electric heaters to melt the ice on the

evaporator surface.

A frost-free refrigerator-freezer (fig. 4) has the evaporator

located outside the refrigerated compartment. On the running

part of the cycle, air is drawn over the evaporator and is forced

into the freezer and refrigerator compartments by a fan. On

the off part of the cycle, the evaporators automatically defrost.

Refrigerator-freezer cabinets are made of pressed steel with

a vinyl or plastic lining on the interior wall surfaces and

a lacquer exterior finish. Most domestic refrigerators have

urethane foam or fiber glass insulation in the cabinet walls.

The side-by-side refrigerator-freezer arrangement has a number

of features not found in other refrigerators. In addition to

the automatic icemaker in the freezer compartment, it has an

option for a cold water dispenser, a cube or crushed ice dispenser,

and a liquid dispenser built into the door.

Back to Top |

Water Coolers and Ice

Machines

Water coolers provide water for drinking at a temperature under

50°F. Two types of water coolers are instantaneous and storage.

The instantaneous type only cools water when it is being drawn;

the storage type maintains a reservoir of cooled water. One instantaneous

method used places coils in a flooded evaporator through which

the water flows. A second instantaneous method uses double coils

with water flowing through the inner coil with refrigerant flowing

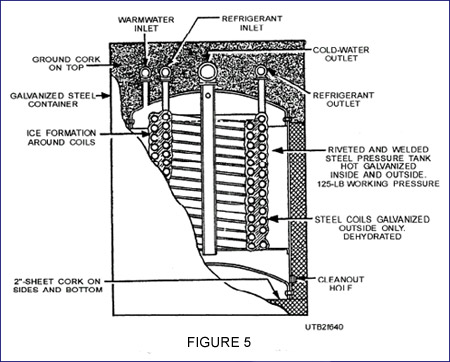

in the space between the inner coil and the outer coil. A third

instantaneous method is to coil the tubing in a water storage

tank. This allows refrigerant to flow through it (fig. 5).

Water coolers are of two basic designs—wall mounted or

floor mounted. Both types are the same in construction and operation;

the only difference is in the method of installation. Water

cooler cabinets have a sheet metal housing attached to a steel

framework. The condenser and hermetic compressor are located

in the housing base, and the evaporator is located in the cabinet

depending on its type of evaporator, but normally under the

drain basin. Most water coolers use a heat exchanger or precooler,

which precools the fresh water line to the evaporator, reducing

cooling requirements for the evaporator. A thermostat, which

is manually set and adjusted, is located in the cooler housing

close to the evaporator.

Ice machines are self-contained, automatic machines, ranging

from a small unit producing 50 pounds of ice per day to a commercial

unit producing 2,400 pounds of ice per day. The primary difference

in the design of these machines is the evaporator. They automatically

control water feed to the evaporator, freeze the water in an

ice cube mold, heat the mold and empty the ice into a storage

bin, and shut down when the storage bin is full.

Floats and solenoids control water flow, and switches operate

the storing action when ice is made. Electrical heating elements,

hot water, hot gas defrosting, or mechanical devices remove

the ice from the freezing surfaces depending on the unit. In

recent years, many companies have begun to manufacture their

units to use HFC R-404a refrigerant instead of HCFC R-22.

Back to Top |

|

Reach-in refrigerators have a storage capacity of 15 cubic feet

or greater. They are mainly used for storing perishable foods,

but they can be found in medical facilities for storing biologicals,

serums, and other medical supplies requiring temperatures between

30°F and 45°F. Standard-size units most frequently used

are those with storage capacities between 15 and 85 cubic feet.

Reach-in refrigerators have a storage capacity of 15 cubic feet

or greater. They are mainly used for storing perishable foods,

but they can be found in medical facilities for storing biologicals,

serums, and other medical supplies requiring temperatures between

30°F and 45°F. Standard-size units most frequently used

are those with storage capacities between 15 and 85 cubic feet.

Single

Door Fresh Food Refrigerator

Single

Door Fresh Food Refrigerator

The

two-door refrigerator-freezer combination is the most popular

type of refrigerator. It is similar to the fresh food refrigerators

in construction and the location of components except it sometimes

has an evaporator for both the freezer compartment and the refrigerator

compartment. Also, if it is a frost-free unit, the evaporators

are on the outside of the cabinet.

The

two-door refrigerator-freezer combination is the most popular

type of refrigerator. It is similar to the fresh food refrigerators

in construction and the location of components except it sometimes

has an evaporator for both the freezer compartment and the refrigerator

compartment. Also, if it is a frost-free unit, the evaporators

are on the outside of the cabinet.